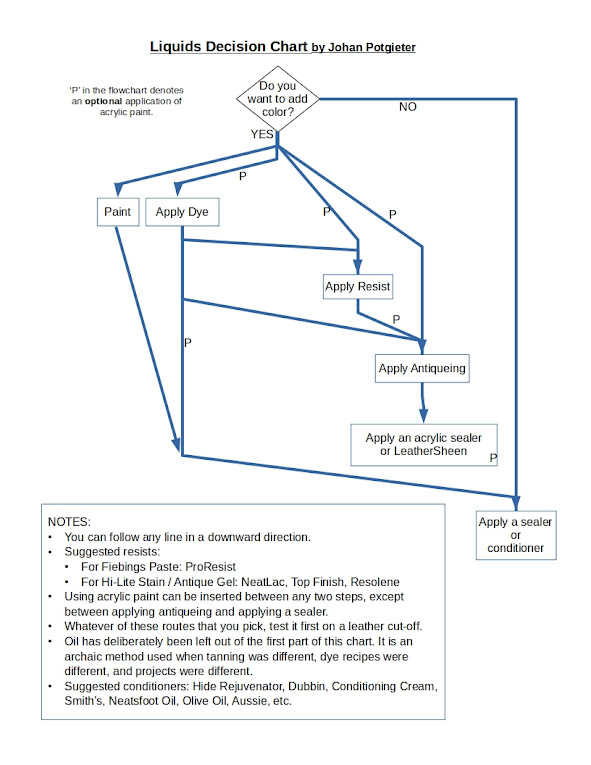

This post is intended for anybody not sure of the sequence of applying dyes, paint, antiques, sealers, and conditioners.

Thursday, July 21, 2022

Liquid Sequence

Sunday, January 24, 2021

Resist and Antiquing

I did a test to show some of the options with resist and antiquing.

This photo shows my preparation for the process:

I first stamped the top piece of leather with the hats and slightly beveled around them.

Then I applied Neatlac in specific spots as I will soon explain. Those areas stayed dark, even after the Neatlac dried, and I realized I would have to do the same on another piece of leather that was tanned differently. You can see the difference in the effect of the Neatlac. I did the same on both pieces, so when I refer to "B", it is the second hat from the left in the top row, on both pieces of leather.

A: No resist, no dye.

B: Both hat and background resisted.

C: Just the hat is resisted with the Neatlac.

D: Only the background is resisted.

E: No resist, no dye.

F: Hat painted with white acrylic paint

G: Background dyed with Java brown water-based dye.

H: Background dyed and hat resisted.

After this, the Hi-Lite stain was applied:

Here is the result:

On both pieces the background dye around G and H almost completely disappeared - I think the Java brown dye and the Chestnut Hi-Lite colors were too close for the dye to show through in contrast.

And here is a quick tip:

In this case however, I wanted to get the Hi-lite stain off as much as possible and also make sure that the color was on as even as possible. To do this, I applied the Neatlac with a sponge as you can see in this video:

*

Thursday, August 20, 2020

COLOR 106 - DYES SIMPLIFIED

[Originally published August 2019]

I do recommend Al Stohlman's book, Coloring Leather, (not How to Color Leather). It is still a very relevant book.

There are a few changes happening in the world of dyes - solvent (spirit based / alcohol based) dyes are being upstaged by the water based dyes. Some states have stopped the sale of solvent (alcohol) based dyes.

Fiebings Pro-dye is a higher quality version of alcohol / spirit based dye - it is simply alcohol based dye (no oil) with a bit of an improved recipe and a superior oil-based pigment - it gives better penetration into the leather and takes a bit longer to dry. The coverage is a bit more even. First choice if you can get it.

Eco-Flow water based dye - the new generation dyes - so far looks to be an equally good choice, mainly because they are proving to be a lot more color fast than the old regular spirit based dyes.

I know your leather craft store is stocked with hundreds of little bottles, so I will expand on this theme as much as I can, but here is the short version:

- The first liquid to hit your leather, is water if you want to tool and/or shape your leather ("casing").

- The next liquid to touch your leather, is dye, if you want to change the color of the leather or parts of the leather.

- The third possible liquid you use, is a resist (in order of preference: Neatlac / Eco-Flo Top Coat / SuperSheen), if you want to shield some parts of the leather by being colored by the next liquid. There is another article on this blog about resisting.

Fiebings Pro Resist only works with Fiebings Antique Paste. - Now you can consider using an antique finish/stain on the leather, if you wish to have an antiquing effect, mostly on tooled leather (it leaves a dark residue in the tool impressions and makes them more pronounced).

- Lastly you add a finish / dressing / conditioner: for working leather I prefer Dubbin, Dr Jackson's, Neatlac or Aussie; for leather that was painted with acrylic paints, I prefer and acrylic finish like Supersheen or Satinsheen.

If you want a light stain and thereby enhance the tooling on the leather, one way you can try is to dye your project with a much diluted (with water) Eco-Flo dye, or spirit based dye diluted with rubbing alcohol. To further emphasize the tooling, you can use an antique finish/stain over the dye - the antique stain will add its own color to the project, unless you have the project fully or partially resisted. For a more subtle effect, the Eco-Flow Hi-lite Stain dilutes very successfully!

I hope this sheds some light! (... and color....)

(Updated 21 October 2019)

Wednesday, August 19, 2020

COLOR 105 USING A BRUSH

Tuesday, August 18, 2020

COLOR 104 ALL-IN-ONE

Monday, August 17, 2020

COLOR 103 ANTIQUEING

[Originally published August 2006]

Applying Antique Finishes

- This step can be left out so that your dye job remains clean and fresh looking.

- Antique Finish/Stain, like Eco-Flo Hi-Lite stain and Antique Gel, can be used after you have optionally dyed leather.

- Although antique finish is water based, it is not an acrylic, so it is not very permanent and will wear and wash off. It has to be sealed with a finish / sealer. For this I like Fiebings Leather Sheen in a spraycan.

The intended use of antique finish is as follows:

- Let your project dry completely after applying water-based, alcohol/spirit-based dye.

- Optionally cover the project with a resist, which can be any of the following : Eco-Flo Top Coat, Neatlac, Supersheen, or RTC.

- Let the resist dry, as in overnight.

- Now apply the antique paste or liquid with a damp sponge very liberally, so that it gets into all your tooling impressions and cracks.

- Have a clean damp sponge or dry paper towel handy and start wiping off the excess finish from the non-tooled areas. You do not want the antiquing to dry and cause streaking on the leather where there is no tooling. Gradually work towards the tooled areas and wipe the excess finish off there as well, leaving only the accentuated tooled areas with finish in.

- Let the antiquing dry overnight again and then apply the finish of your choice to seal the antique.

This video shows how Hi-Lite Stain is applied - the technique is exactly the same for Antique Gel (also by Eco-Flo). You will also see a resist and dye being used first and then how that pans out when you do the antiquing over it.

Here is a long winded "Live" video that shows Hi-Lite stain even used over vinagroon:

(Updated 23 August 2020)

Sunday, August 16, 2020

COLOR 102 DYE BASICS

Leather can be left natural and not dyed - in time it will turn a beautiful honey color.

- You can dye on damp leather - only use stain on dry leather.

- When you apply dye to leather, the leather thinks it is wet, and it will show darker - as the solvent in the dye evaporates, the color will lighten considerably.

It is a good idea to let the project sit for a while to dry before you judge whether you dyed dark enough or not. - Bright colors like turquoises will loose their brilliance as the leather turns naturally darker with exposure to oxygen (oxidation).

- White is not a leather color. White can only successfully achieved on leather if it is applied as part of the tanning process. Basically you can dye leather darker, but never lighter. The one exception is diluted white acrylic paint.

- To dye veg tan leather black, you might consider first dyeing it in a dark shade of brown or navy blue or even purple. If the dye then fades a bit, it will not show the natural light brown underneath. However, nowadays the new black dyes come so strongly pigmented that two coats or a dark undercoat are hardly necessary.

- Make yourself a base of sponge, or layered leather or wood to set the dye bottle in to make sure it does not tip over while you are working - the spirit based dye is evil and WILL climb out of the bottle at every opportunity!

- For the same reason, always close the lid of the bottle when you are taking a breather - an unattended open dye bottle WILL fall over and spoil your project, the tablecloth, the chair upholstery, your pants and the cat and the carpet...! Or all of them!

Hope This Helps!

[Updated Aug 23rd, 2020]

Saturday, November 30, 2019

Color 101

[Originally published August 2008]

This is probably the aspect of leathercraft where there are as many opinions as there are crafters, and most of them will swear by their own methods as gospel truth.

So, I want to give you my opinion as well, but with the hope that it will clarify some of the confusion that exist around dyes, stains, finishes, dressings, conditioners and oils.

This whole discussion will center around vegetable-tan (treebark tanned) leather. This is the only leather to be treated with the products I will discuss.

The basic sequence in any project will more than likely be as follows:

- The project is cut out and tooling / stamping is done.

- The leather is dyed - either completely or selectively. This step can be left out if you want the natural color to remain.

- A optional choice is made between

- a) not using an antique stain,

- b) lightly using an antique stain just to highlight tooling or

- c) making heavy use of an antique stain in such a way as to drastically add to the color of the leather.

- A finish, sealer or conditioner is added to the leather to waterproof and lubricate the leather fibers. This step can NEVER EVER be left out!!!

- The project is assembled.

Putting a dressing on leather will bring out the color of the dyes (make it glow), "waterproof" the leather (your best defense against stains) and make the leather softer (if you have not treated it for the making of armor).

Saturday, April 20, 2019

Oil before Dye

- the leather was tanned with different recipes,

- only alcohol based dyes were available and had very different recipes from the alcohol based dyes of today

- they applied the oil VERY sparingly and let it sit at least overnight to completely even out in the leather