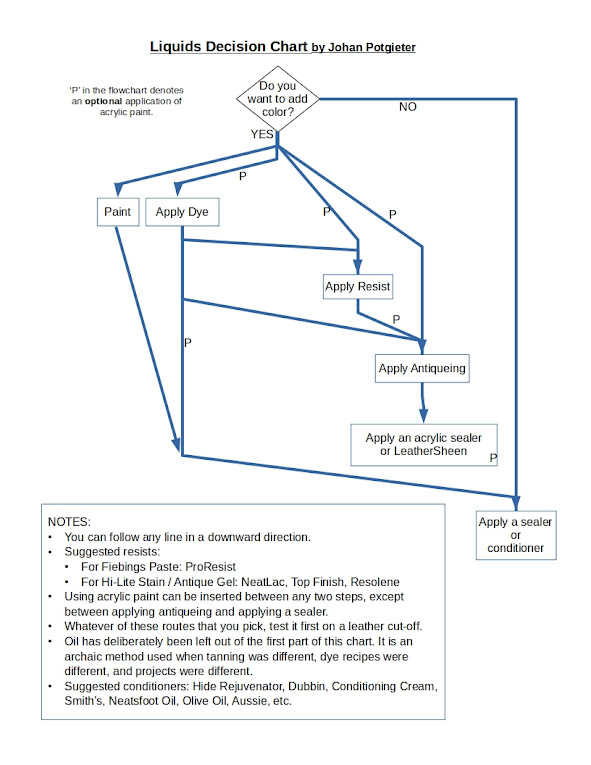

This post is intended for anybody not sure of the sequence of applying dyes, paint, antiques, sealers, and conditioners.

Thursday, July 21, 2022

Liquid Sequence

Monday, January 4, 2021

Cracking Leather

Stop Leather from Cracking

- You can bend the leather while it is damp and the leather can stretch more. This can be when it is still damp from the dye, or you could get the whole piece damp again.

- You can treat the leather with a conditioner such as olive oil, neatsfoot oil or any of the waxy greasy conditioners out there. After it has penetrated the leather, manipulate the leather to give the fibers a chance to work them selves loose and become lubricated.

- Not all leathers are tanned with the same recipe - some may easily accept an aggressive fold and some may crack just because of the way it was tanned.

- The thicker the leather, the further you expect the outer layer to stretch, which could also be a factor.

Thursday, November 5, 2020

Dubbin

- DUBBIN feeds and protects the leather from the inside and replaces all the oils taken out of the leather during the tanning process.

- DUBBIN brings out a deep glowing color in leather. In un-dyed leather it will cause the leather to turn a golden honey color when exposed to light.

- DUBBIN is very good for your hands - especially in winter. I always apply it by hand - it allows me to regulate exactly how much I put on.

- DUBBIN never accentuates stains on leather - it rather tends to clean up any water or light stains.

- DUBBIN Can be used over any dye or finish, such as spirit dyes and water based dyes as well as water based inks.

- DUBBIN allows leather to become supple without loosing its shape - it helps the leather to stay "alive" and always as beautiful as new.

- 1 kilogram lard [2 lb] - I prefer sheep lard. It has to be rendered - cut it up and boil it in water until the lard separates out clear from the water and gunk. Pour it off so that you can let it cool off and solidify.

- Less than 100 grams of beeswax [1oz or less]

- 1/2 liter of Cod Liver Oil [16 fl oz].

If the thought puts you off, replace it with Neatsfoot oil or olive oil, in fact, any plant or animal oil, but definitely not a mineral oil (that will attack your leather).

I have doused a piece of leather in Cod Liver oil - it smelled fishy for four hours, and then the oil and leather started to talk to each other and all that was left, was a very traditional leather smell.

Cod Liver oil used to be a very traditional oil used in working with leather and some ascribe the very romantic smell of the previous century car interiors and saddles and leather goods, to Cod Liver oil. - 60 ml of Lanolin [2 fl oz]. I have found pure lanolin sold in pharmacies for use by breastfeeding mothers.

- 60 ml of Glycerin [2 fl oz].

I make my own Dubbin as a leather dressing - mainly for veg tan. I am curious as to the ingredients I use and how meaningful they are (are they all necessary?) Beeswax Sheep Tallow Cod Liver Oil Glyserin Lanolin

I see on the ALCA dictionary that there is also mention of aluminum stearate in dubbin - what is its purpose and where can the-man-on-the-street buy this?This was the answer I got back:

Each of the materials in your dubbin has a unique character and therefore imparts a special trait to the leather.

The wax protects the surface and adds that unique feel to the treated leather.

The tallow penetrates a little better, but also contributes to that waxy nature, but also has a lower melting point, so it changes more effectively when warmed slightly than the wax which remains solid to a bit warmer condition.

The fish oil penetrates deep and softens as well as providing anti-oxidant properties and even some tanning when heated.

The glycerin is a good humectant and keeps the leather from over drying by pulling moisture from the air.

Lanolin is also unique, though some folks are sensitive to lanolin and should always be advised that it is in the leather. This sheep byproduct has long been taunted as a great soften and water repellent for leather.

Clearly the amount of each of these materials in the dubbin can be a major issue, but that is something that I am sure you have seen with time and experience as you adjust your formula.

Aluminum stearate is just soap, though most would probably consider it more a grease than a soap. It combines a wax and humectant roll, but just as most leather experts warn against the use of saddle soap, I think you will quickly see that this soap really has little to offer your mix.

The biggest issue with soaps and leather is that soaps are made under highly alkaline conditions, and unless that basicity (alkaline pH) is neutralized it can carry terrible consequences to the acid leather.

Published Aug 2016

Updated Jul 2017

Monday, November 2, 2020

First test of WaterBased Neatlac

Jan 2019: I got hold of the new Neatlac (waterbased) and so I have started to test to see if it lives up to the quality of its obnoxious, but good quality highly used, predecessor.

So [A] I used it on Eco-Flo Water Stain. It made the color pop beautifully, but arrow [1] and arrow [2] shows that you should not let it pool anywhere (I put it on liberally so that it would pool so that I could see the effect).

In [B] I used it as a resist under Eco-Flo Hi-liter - worked very well as a resist (in all of these tests I only used 1 single layer of Neatlac).

Piece [C] was first stained with Eco-Flo Hi-liter, and then the Neatlac was used as a sealer over it (also used as sealer on piece [B] ).

Arrow [4] shows a spot where the brush did pick up the stain - so I am going to stay with LeatherSheen from a spraycan to seal in any antique stain. My friend Jim Linnell showed me how to put a sealer like this on with a sponge: you simply work it until it is even - the sponge will pick up some of the antiquing, but you just keep working it until it shows even.

The difference between the light and dark indicated by arrow [3] is merely a border between more and less oxidation - the Neatlac had no effect there.

In the second photo, the arrow shows a border between Neatlac and no Neatlac - [a] has Neatlac as a resist to Fiebings Antique Paste, and [b] has no resist.

So it looks like Pro Resist by Fiebings is a better resist for its own paste.

Piece [c] simply had Neatlac as a topcoat over the natural leather - no color - nice and shiny. I think with practice and more experiments this product might just be as good as it was when it was still a bit poisonous many years ago.

First published Jan 2019